PALLETING

SOTRA FEED FOR PALLETING

We believe it is of the utmost importance that prior to palletising, you must install accumulation paths – both when dispensing to the palletising robots, and prior to dispensing.

This is sufficiently long so that the palletising robots can work continuously regardless of the time required for pallet shifts.

Our recommendation will be at least 15 boxes on accumulation tracks.

SOTRA PALLETING

When installing one or more palleting robots in production it is of the utmost importance to use both track changers and accumulation tracks in advance before the output of the robots.

This allows maximum utilisation of the robot’s capacity. Which, when properly installed, will allow you to achieve approx. 12 box handles / min.

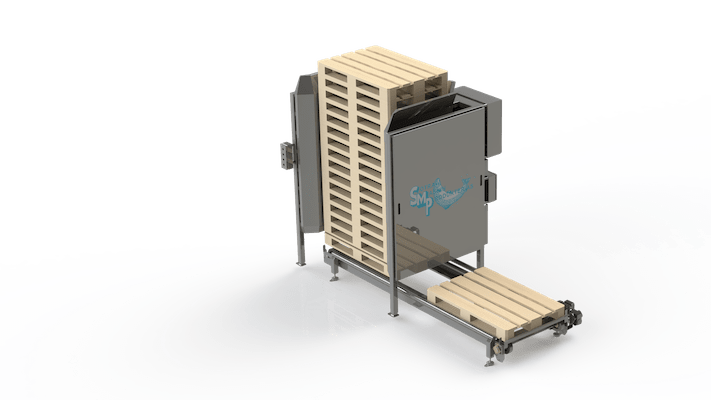

SOTRA PALLET DESTACKING

Already when installing a palleting robot you have the benefit, and not least security, of installing automatic pallet feeding.

With only one robot, a pallet magazine with automatic feeding to the pick-up position for the robot is installed. When installing this equipment, one can expect a productivity increase of 15-20% on the robot.

Our company, in collaboration with the industry, has developed a pallet stacker that delivers the pallet stack down the output lanes, and then

retrieves pallet storage. This provides a smooth and gentle feed of thumb pallets.

SOTRA PALLET OUTPUT

When installing 2 or more robots, automatic pallet feeding is necessary to maintain the productivity of the robots.

When installing runways or chain lanes for pallet delivery, it is essential (seen from our side) that the delivery trolley is also a transport unit for empty pallets. This avoids the use of the robot’s palleting time to retrieve empty pallets and increases productivity.